Best practices

5 things Support Teams need to know now during an incident

When an incident hits — whether it's a broken seal, a temperature deviation, or a contamination alert — the clock starts ticking fast.

And if you're in a customer-facing support role, you're caught in the middle: your customers want answers, your internal teams need time to investigate, and reputations are on the line.

In food and agri logistics, incidents are inevitable. But how you respond is what builds (or breaks) trust. The difference between a chaotic scramble and a confident resolution usually comes down to one thing: preparedness.

Here are five things every support team should know and have at their fingertips during an incident, especially if you're supporting customers across multiple sites, systems, and regions.

1. Know what happened and when

Before you answer any customer, you need one source of truth: What exactly happened, and when? Waiting on emails or digging through spreadsheets isn't fast enough. Support teams need real-time access to the incident timeline:

When was the shipment packed and loaded?

What were the last recorded temperature checks?

Were there any non-conformance flags?

If your operations team is using digital checklists and photo logs, you should have that information within minutes — not hours.

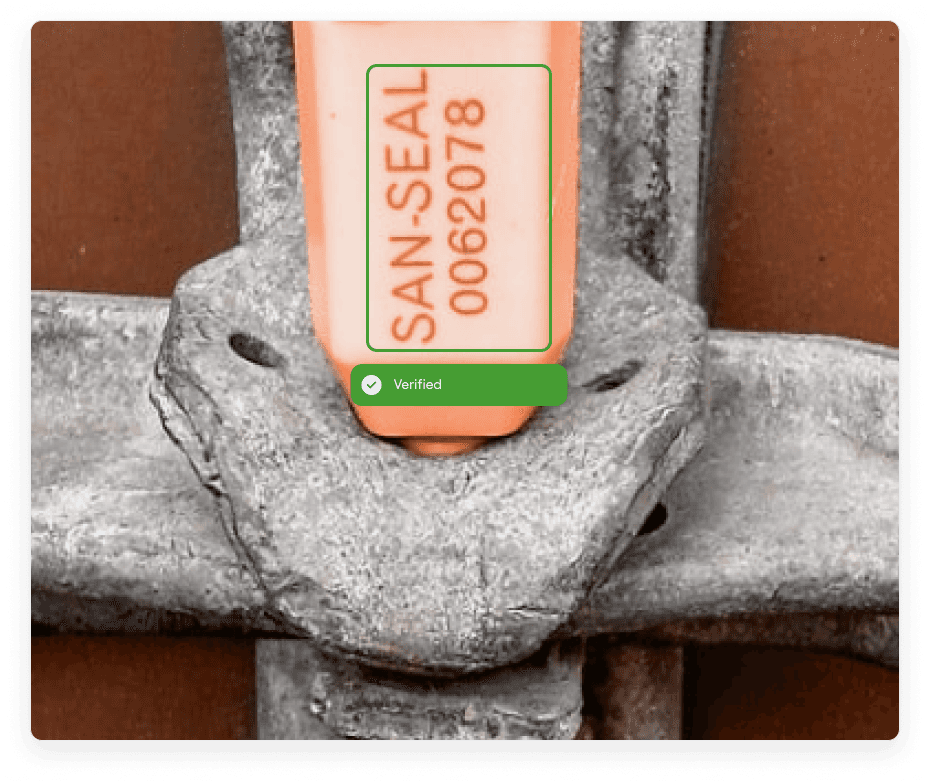

2. Access to verifiable evidence

Saying “we’re looking into it” only works once. The next question is always: Can you prove it? During an issue (damage or another), customers expect evidence:

Photos of loading and sealing

Temperature graphs from point A to B

Checklist logs with timestamps and operator names

If you're relying on manual forms or scattered folders, that response time drags. Support teams need tools that tie QA data directly to shipments, SKUs, and timeframes — so you can send visual proof, not vague updates.

3. Understand which SOPs apply

Not every product, route, or customer has the same requirements. So when something goes wrong, support teams should know:

What was the agreed-upon process for this shipment?

Which SOPs were in place (e.g., allergen handling, temperature control)?

Were there customer-specific instructions involved?

If the shipment involved sensitive goods like fresh produce or dairy, documentation around those SOPs should be easy to retrieve — and clear enough to share with the customer if needed.

4. Know who owns the next step

During QA incidents, the last thing you want is finger-pointing or email loops. Support needs to be plugged into the incident resolution flow, so you know:

Who is investigating the root cause?

Who’s responsible for documentation and response?

What timeline can we realistically promise the customer?

Having a clear escalation matrix and knowing which teams are using tools like Cargosnap to document and flag issues in real time can save hours of back-and-forth and ensure a coordinated response.

5. Be ready to communicate with confidence

At the end of the day, your customers don’t just want a resolution. They want to know you're in control. When support teams have access to clean data, clear logs, and visual documentation, they can respond with:

Specifics (“The pallet was sealed at 08:53 and stored below 5°C until dispatch”)

Evidence (photos, logs, alerts)

Assurance (“Here’s what we’ve already corrected to prevent a repeat”)

This turns a reactive support role into a proactive, trusted partner — especially when working with high-value clients, regulatory scrutiny, or sensitive products.

Incidents are inevitable. How you respond makes all the difference.

In the fast-paced world of food and agricultural logistics, customer expectations are continually rising. Support teams can no longer wait for quality or operations to chase down information. They need direct access to clean, traceable, real-time data — so when things go wrong, they can respond fast, communicate clearly, and protect the relationship.

That’s exactly where Cargosnap comes in.

Cargosnap gives Customer Support Managers real-time visibility into operations through photo-based inspection reports, automated updates, and timestamped documentation. All linked to specific shipments, locations, or products. It enables faster resolutions, fewer escalations, and more confident communication with customers.

With Cargosnap, support teams stop being just ticket managers. They become proactive problem-solvers — trusted partners when it matters most.