Compliance

3 quality assurance mistakes your WMS won’t catch (and how to avoid them)

Most warehouse management systems (WMS) do a great job of tracking inventory and managing orders. But when it comes to quality assurance (QA), especially in fast-moving, regulated sectors like food and agriculture, there are critical gaps WMS platforms simply weren’t built to cover. If you’re relying solely on your WMS to protect your product quality and compliance, you may be missing key risks.

Here are 3 quality mistakes your WMS won’t catch, and what you can do about them.

1. No visual proof of product condition

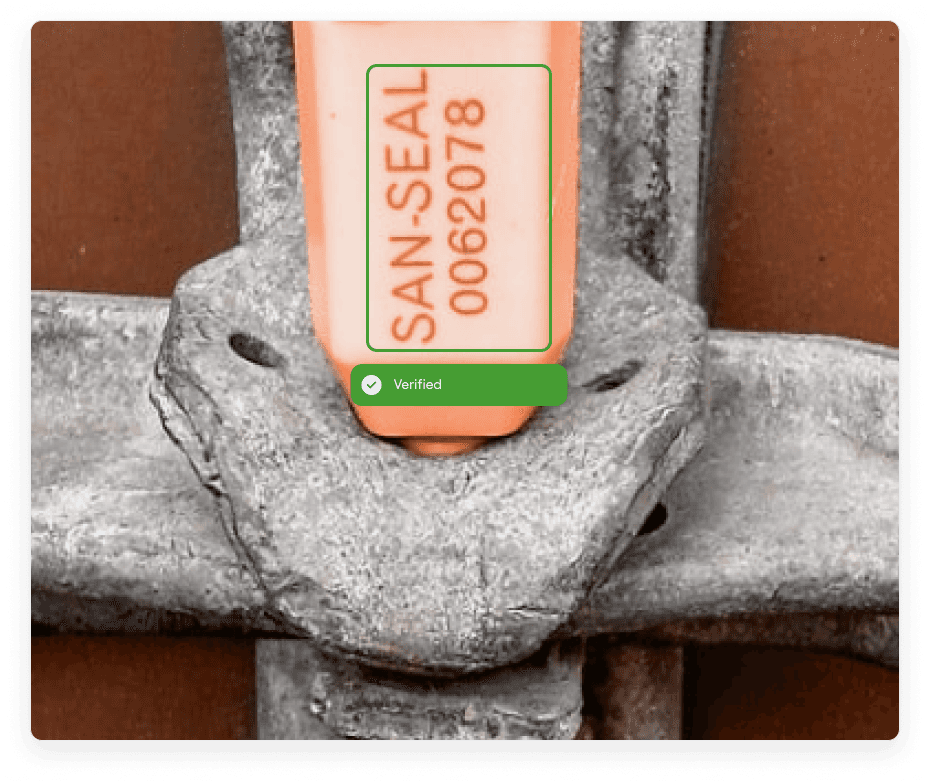

While your WMS is essential for tracking inventory and shipments, it falls short when it comes to capturing proof of product condition. Something that’s critical in food and agriculture logistics. Without visual evidence like photos or inspection notes, there’s no way to confirm cleanliness, label accuracy, or seal integrity. This gap increases the risk of disputes, delays investigations, and limits the ability to drive meaningful improvements in quality and compliance.

2. Inconsistent QA checks across sites

For companies with multiple warehouses, ensuring consistent QA procedures can be difficult. Depending on who’s working, when, and where, the same inspection process might be executed differently, or skipped entirely. Your WMS won’t flag these inconsistencies. The result is higher risk for non-compliance, contamination, and slower investigations when something goes wrong. By standardizing QA checklists and digitizing them, you can ensure uniform execution, photo-backed accountability, and centralized oversight across all sites.

3. Manual workarounds create data silos

When engineers or warehouse staff fill in QA gaps manually—using spreadsheets, paper forms, or photos on personal phones—it fragments the process. None of this critical information is connected to your WMS or easily accessible to other departments like QA or Customer Support. These data silos limit traceability and slow response when issues arise. A digital inspection platform helps close this gap by integrating with your workflows and consolidating all QA data in one place.

Go beyond your WMS possibilities

Your WMS is essential for operations, but it wasn’t built for QA. If you want true visibility, defensibility, and control over product quality, you need tools that close the QA gap. Start with visual inspections, standardized checks, and centralized documentation—and let your WMS do what it does best.