Insights

Why KPIs matter for business success

In logistics, every delay, deviation, or damaged shipment can ripple through the supply chain—costing time, money, and customer trust. For logistics engineers, success depends on more than just keeping goods moving; it’s about continuously improving processes and preventing problems before they escalate. That’s where Key Performance Indicators (KPIs) come in. By tracking the right KPIs, logistics teams turn daily operations into measurable insights, making it easier to spot inefficiencies, reduce risks, and prove the value of their work.

What is a KPI (Key Performance Indicator)

A Key Performance Indicator (KPI) is a measurable value that shows how effectively your logistics operations are performing against objectives. For logistics engineers, KPIs ensure that operations aren’t just running—but improving.

Why KPIs are critical in Logistics

Operational Alignment: KPIs link warehouse, transport, and quality control performance to wider business goals.

Process Visibility: They give real-time insight into where bottlenecks, delays, or inefficiencies occur.

Continuous Improvement: Data-driven tracking helps engineers fine-tune workflows and reduce waste.

Compliance & Safety: KPIs tied to audits, inspections, and standards keep companies aligned with regulatory requirements.

Types of KPIs in Logistics

Strategic KPIs – High-level performance measures like On-Time In-Full (OTIF) delivery rate or total logistics cost as % of sales.

Operational KPIs – Short-term metrics such as average loading/unloading time per truck or order picking accuracy.

Functional KPIs – Tailored to specific teams:

Warehouse: inventory accuracy, inspection pass rate

Transport: claims ratio, kilometers driven empty

Quality: number of deviations per 1,000 shipments

Leading vs. Lagging –

Leading: % of workflows completed on time (predicts issues before they escalate).

Lagging: number of customer complaints due to cargo damage (tracks results after the fact).

KPIs vs. Metrics in Logistics

While all logistics metrics are useful, not all are KPIs.

A metric might be total shipments per day.

A KPI is % of shipments inspected with no non-conformities, because it directly shows progress toward quality and compliance objectives.

How to develop effective logistics KPIs

Start from Objectives – e.g., “reduce cargo claims by 20% this year.”

Apply SMART Criteria – KPIs must be specific, measurable, realistic, relevant, and time-bound. Example: Reduce average claim resolution time to <48h by Q4.

Assign Ownership – Each KPI should have a responsible manager or engineer.

Review Often – Logistics conditions shift—seasonality, regulation, customer demands—so refine KPIs quarterly.

Anatomy of a strong Logistics KPI

Every KPI should define:

Measure: e.g., Average container inspection time

Target: <10 minutes per inspection

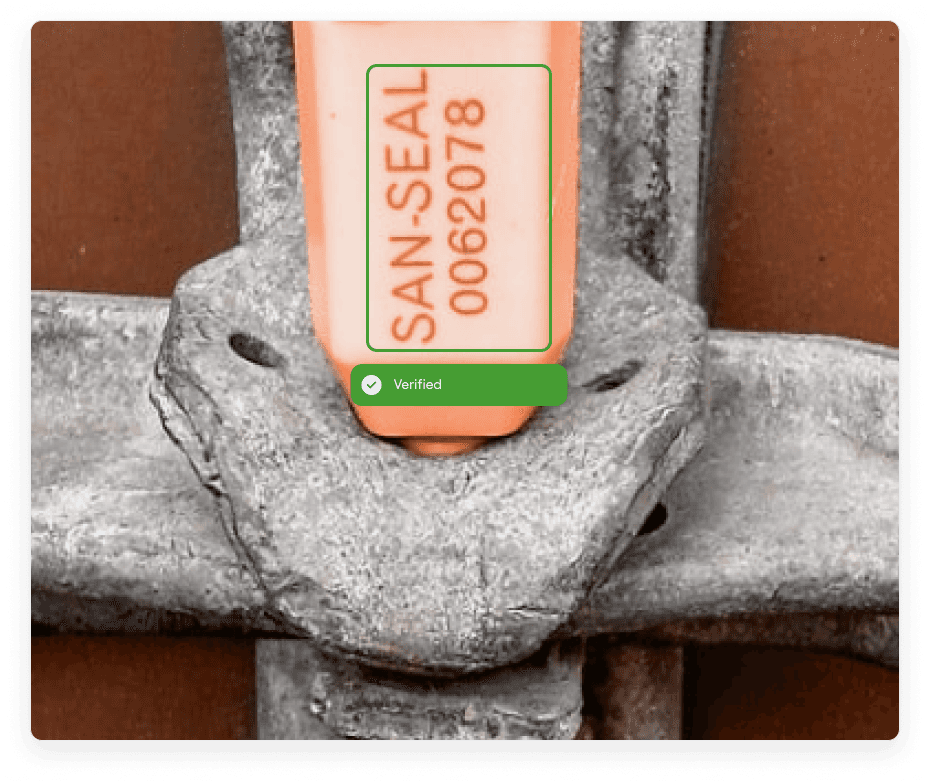

Data Source: CargoSnap inspection reports, WMS data

Frequency: Weekly / Monthly review

KPIs examples for your operations

Area | Example KPI | Why It Matters | |

|---|---|---|---|

Transport | % of shipments delivered OTIF | Ensures service reliability and customer trust | |

Warehouse | Average loading/unloading time per vehicle | Highlights bottlenecks and productivity gaps | |

Quality | % of shipments passing inspection first time | Prevents costly rework, improves compliance | |

Cold Chain | % of temperature deviations flagged early | Protects sensitive cargo (food, pharma, agri) | |

Claims | Number of claims per 1,000 shipments | Tracks financial & reputational risk | |

Sustainability | Empty kilometers as % of total distance |

|