Why do 50% of warehouse companies perform cross-docking operations?

Cross docking: understanding the concept and definition

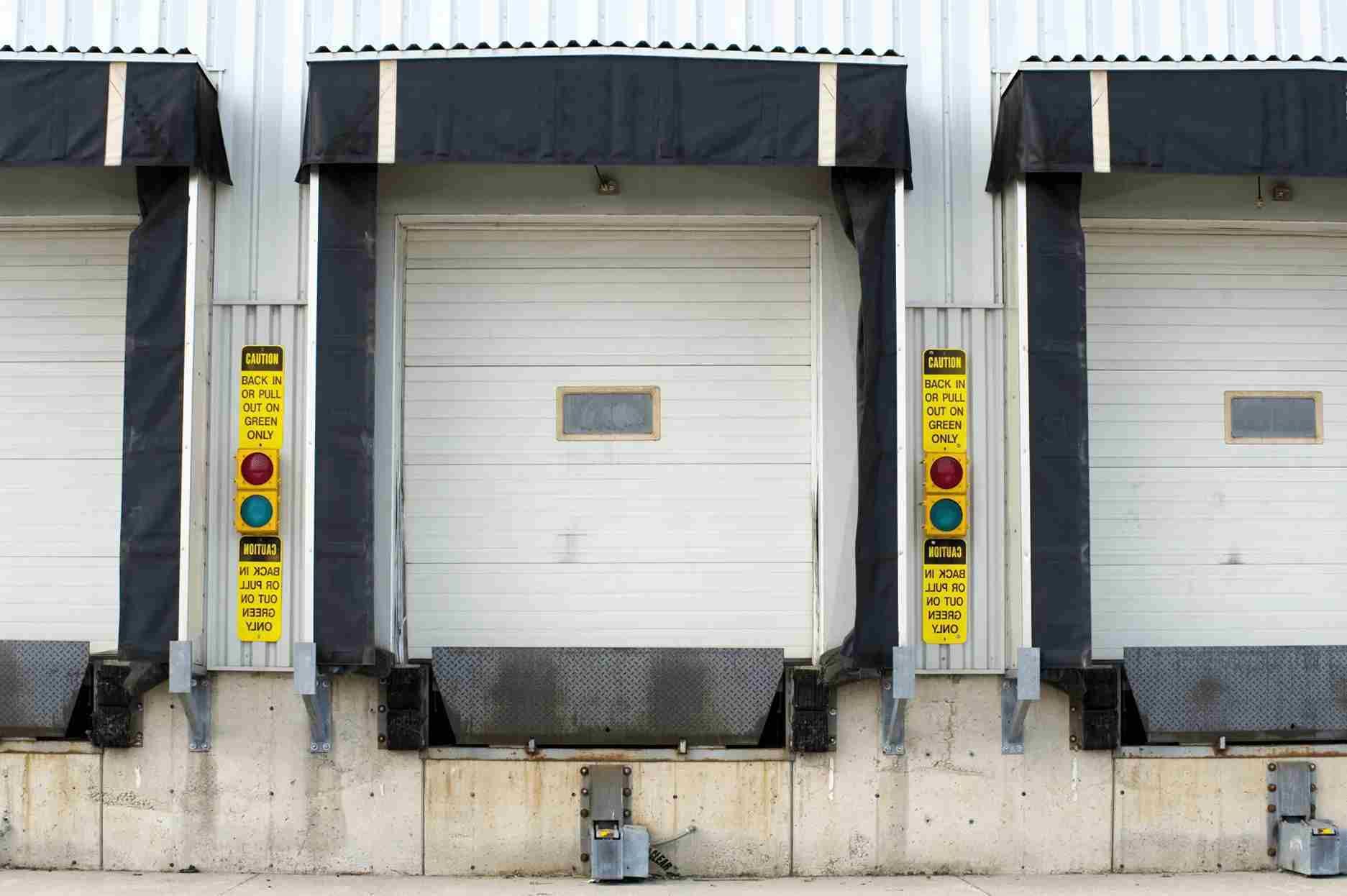

Cross-docking is a logistics model that involves the unloading of cargo and immediate re-loading onto another transportation with little to no storage. Since products spend less or no time in the warehouse, the handling process is simplified, and storage costs are reduced.

Usually, the goods are unloaded from the supplier into the inbound dock, sorted at the cross-docking warehouse, and straight loaded onto another truck that goes to a customer or retailer.

Why do businesses operate cross docking warehouses?

The typical reason to build such operations is that it is cost prohibitive to have inventory and/or Distribution Centers (DCs) everywhere. Cross docking allows for fast, lean, and highly granular delivery operations.

The speed and effectiveness of handling goods have become essential for companies to stand out from the crowd. Amongst the various benefits, cross-docking allows businesses to reduce lead time in shipping and improve customer satisfaction.

Benefits

- Save time and labor costs as cross docking requires little or no goods handling.

- Reduce distribution costs.

- Improve customer satisfaction: faster shipping from producer to customer.

- Reduces the need to store products in the warehouse, thus reducing inventory holding costs and storage costs.

- Ability to reach several locations with small deliveries.

Types of cross-docking

Consolidation cross-docking

Consolidation cross-docking involves multiple shipments from different trucks and transferring them into one larger load. Usually, the goods need to be stored at the warehouse temporally until they are ready to be loaded into an outbound truck.

Sometimes shipping small loads individually is not cost-effective, so consolidation cross-docking helps reduce shipping costs.

Deconsolidation cross-docking

Deconsolidation cross-docking is the opposite of the consolidation method. Instead of having products from different trucks and combining them in one, deconsolidation cross-docking takes one large load and breaks it down into smaller parcels to go on different trucks.

This is used in the direct-to-buyer approach when the supplier sells directly to buyers without any retailers or wholesalers.

Continuous cross-docking

The most common type of cross-docking is called continuous cross-docking, which is used for direct flow between the inbound to outbound logistics products.

Typically, the inbound truck arrives at the warehouse and then directly transfers the goods to the out truck.

What kind of products can you cross-dock?

Cross-docking works best with consistent demand, high volume, and fast-moving goods. Here are some everyday products that are suitable for cross-docking.

- Perishable food that requires immediate delivery.

- Staple retail goods in constant demand.

- Pre-picked and pre-packaged orders from another warehouse.

- High-quality items that don't require quality inspections during goods transit.

How to perform cross-docking inspection faster?

If you are looking for a tool where you can have an overview of all cross-docking loads and assure your customers that their products are being shipped out in perfect condition?

Cargosnap makes your inspections faster by giving end-to-end supply chain visibility and allowing your team to store visual cargo inspections and documents in one place.

Want to know more about how your team can inspect goods with their smartphone, create checklists, fill out forms, and share information in real-time?