Digital transformation

Why most warehouse tech fails to stick (And what to do differently)

We’ve all seen it before. A new system gets rolled out. It starts strong. A new app or system is introduced. The teams are trained. There’s a short burst of activity. And then… the old ways quietly return. Paper logs. Side spreadsheets. WhatsApp photos. The “new solution” becomes yet another tool that never quite caught on.

And the most common pattern shows up again and again: technology is implemented with high hopes, only to fade out a few months later.

This cycle is frustrating, but it's also completely understandable.

The real reasons

Most warehouse technology fails not because it’s poorly made — but because it wasn’t designed for the way people actually work. Especially in environments like food and agriculture, where things move fast, conditions vary by season or shift, and teams need tools that fit into their flow — not the other way around.

The problem is rarely technical. It’s operational. It’s cultural. And too often, it’s a disconnect between what a tool assumes, and what real teams need. Here’s where that disconnect usually happens: Tools ask for data at the wrong moment — when hands are full or priorities are elsewhere. Interfaces are clunky or overly complicated, slowing people down instead of helping them move faster. The system feels disconnected from the rest of the operation — like an extra step, not part of the process. The people using it weren’t consulted — so it doesn’t reflect the actual challenges on the floor. For food and agri logistics, where quality, traceability, and compliance are daily concerns, these gaps aren’t just inconvenient — they’re risky.

Based on our experience, the warehouse teams that make technology stick take a distinct approach. They focus less on features, and more on fit.

1. They begin with real workflows.

Before configuring anything, successful teams start by understanding where the work is actually happening — and where it breaks down. That insight shapes the design and rollout of new tools, ensuring they match reality on the ground.

2. They prioritize ease of use.

Tech adoption only works when the learning curve is minimal. Checklists should feel like checklists. Photos should be quick to snap and share. Interfaces need to be intuitive for teams who don’t have time for trial and error.

3. They make tech part of the routine — not an add-on.

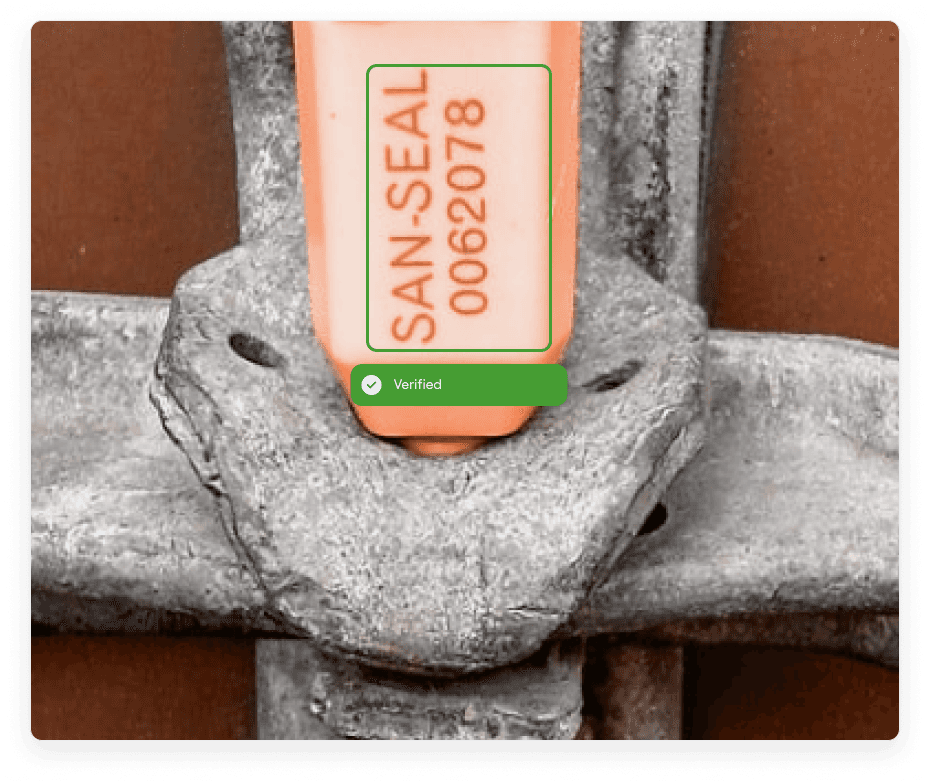

When a tool integrates smoothly with the existing systems (WMS, ERP, QA tracking), it becomes part of the daily rhythm. And when it’s tied to actual inventory, locations, or batches, it gives real traceability — not just data sitting in isolation.

4. They involve the people who use it.

When warehouse teams are part of the rollout — giving feedback, shaping forms, testing on real shifts — adoption happens naturally. People support what they help build. At Cargosnap, we’ve seen the difference this makes. When tech reflects the way your team works — and not just the way someone thinks it should work — it becomes a tool that empowers, not frustrates.

The goal isn’t more dashboards or more data. It’s confidence. It’s traceability. It’s knowing the system will support the process, not hold it back.

Real change doesn’t come from more tech — it comes from a better fit.

It’s easy to think the solution to operational challenges is just adding more technology — another app, another platform, another integration. But more tech doesn’t automatically mean better outcomes. In fact, when tools don’t fit into the way your teams actually work, they can add friction instead of removing it.

What truly drives change is when technology seamlessly integrates into the existing workflow — when it feels like a natural extension of the work, not an interruption. That’s when adoption happens organically. That’s when checklists get completed, photos get captured, and quality records are logged — not because someone is told to, but because the system actually helps them do their job better.

It’s not about having the most features. It’s about having the right ones — in the right place, at the right time, for the right people.

That’s what makes technology stick. That’s what builds trust. And that’s what leads to real, lasting change inside the warehouse.