Compliance

Building a Quality Assurance system

In logistics, quality isn’t optional—it’s the backbone of trust between manufacturers, service providers, and customers. For logistics engineers, every inspection, workflow, and report plays a role in preventing costly mistakes and ensuring compliance. That’s where a Quality Assurance (QA) system comes in. By standardizing processes, reducing variability, and creating reliable audit trails, QA systems give engineers the structure they need to keep operations consistent, efficient, and ready for any challenge.

What is a Quality Assurance system?

A Quality Assurance (QA) System is a structured assembly of standards, protocols, and workflows designed to consistently ensure that logistics operations meet both internal expectations and external regulations. It integrates policies, procedures, and resources to systematically manage quality across the supply chain

Why QA Systems Matter in Logistics

Consistency across the supply chain

QA systems anchor every stage—from loading docks to transit to delivery—in uniform standards to reduce variability and errors.Process-based integrity

Rather than merely inspecting the end result, QA systems embed quality checks into every step, reducing defects before they accumulate.Regulatory & customer confidence

Implementing QA systems signals compliance and reliability—benchmarks valued in industries like food, pharma, and perishables.Continuous feedback loops

QA systems promote continuous improvement via audit trails, root cause analysis, and corrective measures—keeping logistics operations agile and responsive

Core components of a logistics quality system

A robust quality assurance framework should include:

Standard operating procedures (SOPs)

Clearly defined steps for inspections, loading, unloading, and handling of sensitive cargo.Document and data control

Version-controlled forms, inspection reports, and audit logs—all easily retrievable—are essentialTraining & competency tracking

Regular training ensures inspections and quality tasks are performed accurately.Corrective & preventive action (CAPA)

When a deviation occurs, the system should guide root cause analysis and corrective steps to mitigate recurrenceAudits & performance reviews

Scheduled checks against standards, plus reviews of metrics like damage claims, OTIF (On-Time In Full), or inspection pass rates, help refine operational resilience.Supplier & vendor integration

If your logistics depend on external partners—like trucking or loading crews—define QA checkpoints and evidence requirements from the start

Quality assurance vs. Quality control

Preventing issues vs. catching them

Quality Assurance (QA) is proactive—it builds systems that prevent errors throughout the logistics chain

Quality Control (QC) is reactive—it inspects and rejects issues after they occur. While QC is essential, the logistics priority is to reduce reliance on it through QA-informed workflows.

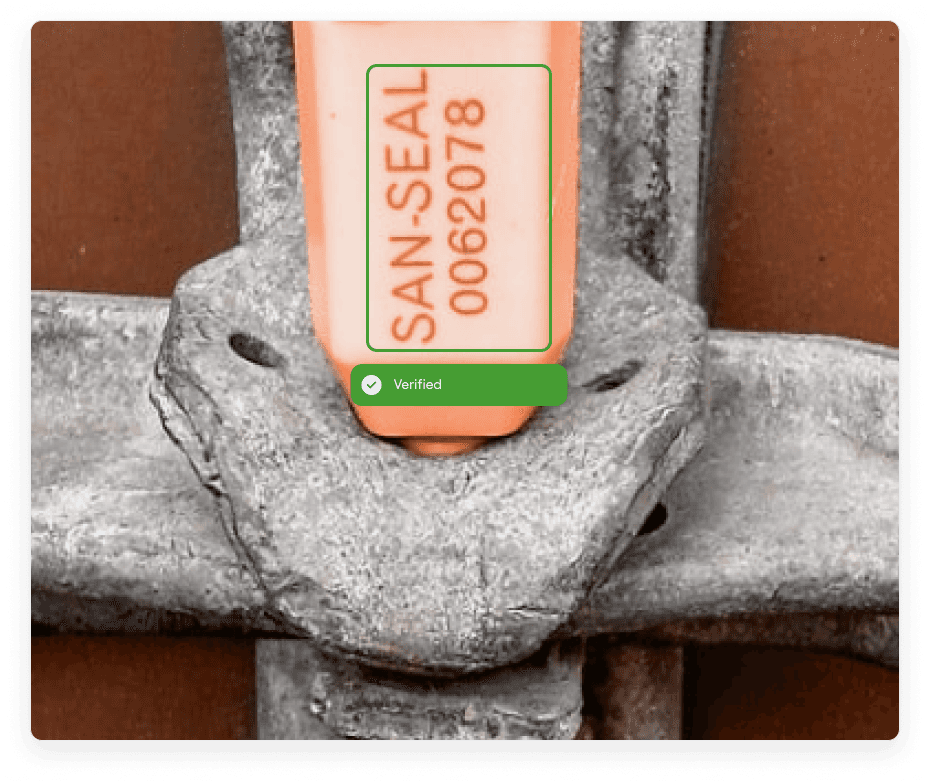

Example in logistics: A QA process might require barcode and seal photo documentation before a load departs. QC only becomes necessary if a reported mismatch triggers a check mid-transit or at destination.

Use case example

Objective: Reduce cargo damage incidents by 50% within 6 months.

SOP: Clear photo requirements of pallet loading, packaging, and seal integrity at dispatch.

Data Capture: Document defects, carriers, and routes.

CAPA: Investigate root causes when recurrent damage appears (e.g., packaging method, handling practices).

Review: Monthly KPI dashboards (damage rate, inspection pass rate, claim resolution time).

Refinement: Update training modules and SOPs based on trends and CAPA outcomes.

Building a strong Quality Assurance system starts with having the right tools in place for inspections, audits, and reporting. To make it easier, we’ve prepared ready-to-use templates designed for logistics quality checks, covering container inspections, warehouse audits, cold chain monitoring, and more.