Material handling

Cutting costs from the ground up: material handling data and cost-to-serve

When logistics teams talk about cutting costs, the conversation usually starts at a high level: transport rates, network design, contracts, automation investments.

But in many operations, the biggest cost leaks don’t live in spreadsheets or planning tools.

They live on the floor. In material handling.

Every loading, unloading, inspection, and internal movement carries cost. And when those moments aren’t visible or measurable, cost-to-serve becomes an estimate rather than a fact.

Cost-to-serve isn’t decided in theory. It’s decided in execution.

n many organizations, cost-to-serve is still calculated using averages such as standard handling time per shipment, assumed labor costs, and fixed process models. In reality, however, cost-to-serve varies constantly: by customer, by product, by shift, by operator, and even by day. And most of that variation doesn’t show up in planning models. It shows up during material handling, where small differences in execution quietly accumulate into significant cost.

The blind spot: material handling without data

In many operations, material handling is still documented through manual checklists, photos stored outside operational systems, and notes spread across tools or teams. Critical context often lives in people’s heads rather than in structured data. As a result, there is a gap between what actually happens on the floor and what can be analyzed afterward. Without structured handling data, teams struggle to compare cost-to-serve accurately across customers, explain why certain shipments are consistently more expensive, or separate one-off incidents from structural problems. Optimization efforts then focus on what is visible at the planning level, while execution inefficiencies continue underneath.

How material handling data changes the cost conversation

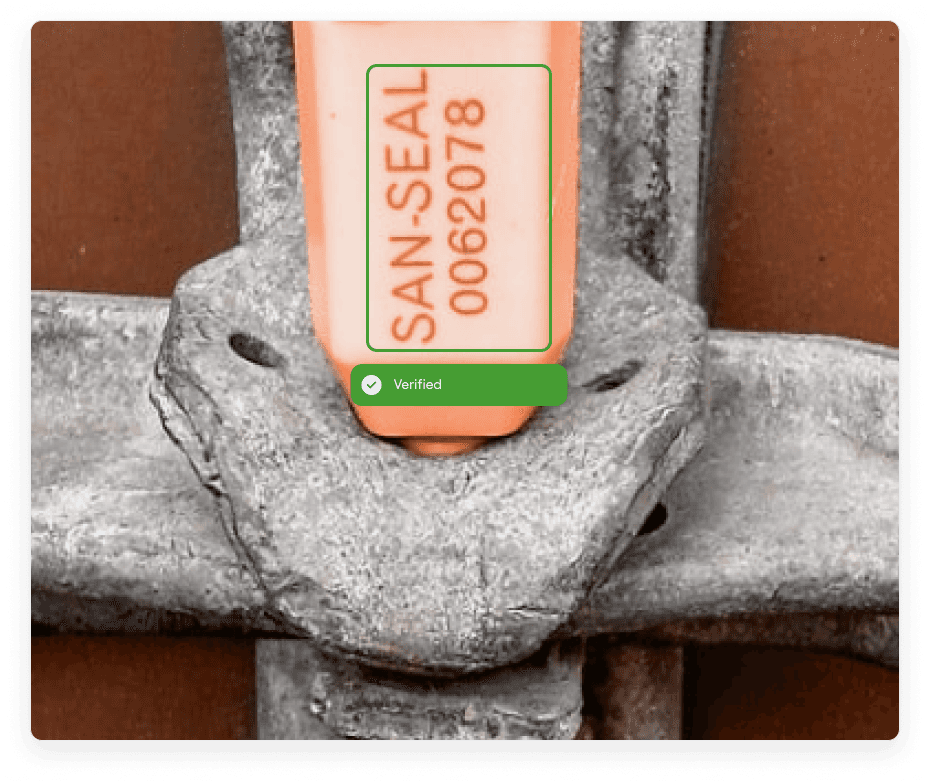

When material handling becomes visible and measurable, the cost conversation shifts from assumptions to evidence. Teams gain insight into how long handling steps actually take, where exceptions occur most often, and how rework, damage, or non-compliance affects cost. Variability between sites, shifts, and partners becomes explicit rather than anecdotal. Cost-to-serve stops being a static financial model and becomes a living operational metric that reflects reality on the floor.

From firefighting to cost control

Without handling data, cost reduction often looks like firefighting: reacting to incidents, managing claims after the fact, and spending time reconstructing what happened instead of preventing it from happening again. With structured handling data, teams can identify recurring patterns early, link cost directly to execution moments, and focus improvement efforts where they will have the biggest impact. Especially in high-volume operations, small inefficiencies repeated thousands of times can quietly erode margins unless they are made visible and addressed systematically.

Cutting costs starts on the floor

If cost-to-serve matters more than ever, and for most logistics organizations it's number one priority, material handling can no longer remain a blind spot. You cannot control what you cannot see, and you cannot reduce costs you cannot explain. Sustainable cost reduction rarely comes from squeezing harder at the top. It starts at the bottom, by making the physical reality of operations visible, measurable, and actionable — one handling moment at a time.

See how a digital material handling platform makes cost-to-serve measurable in practice.